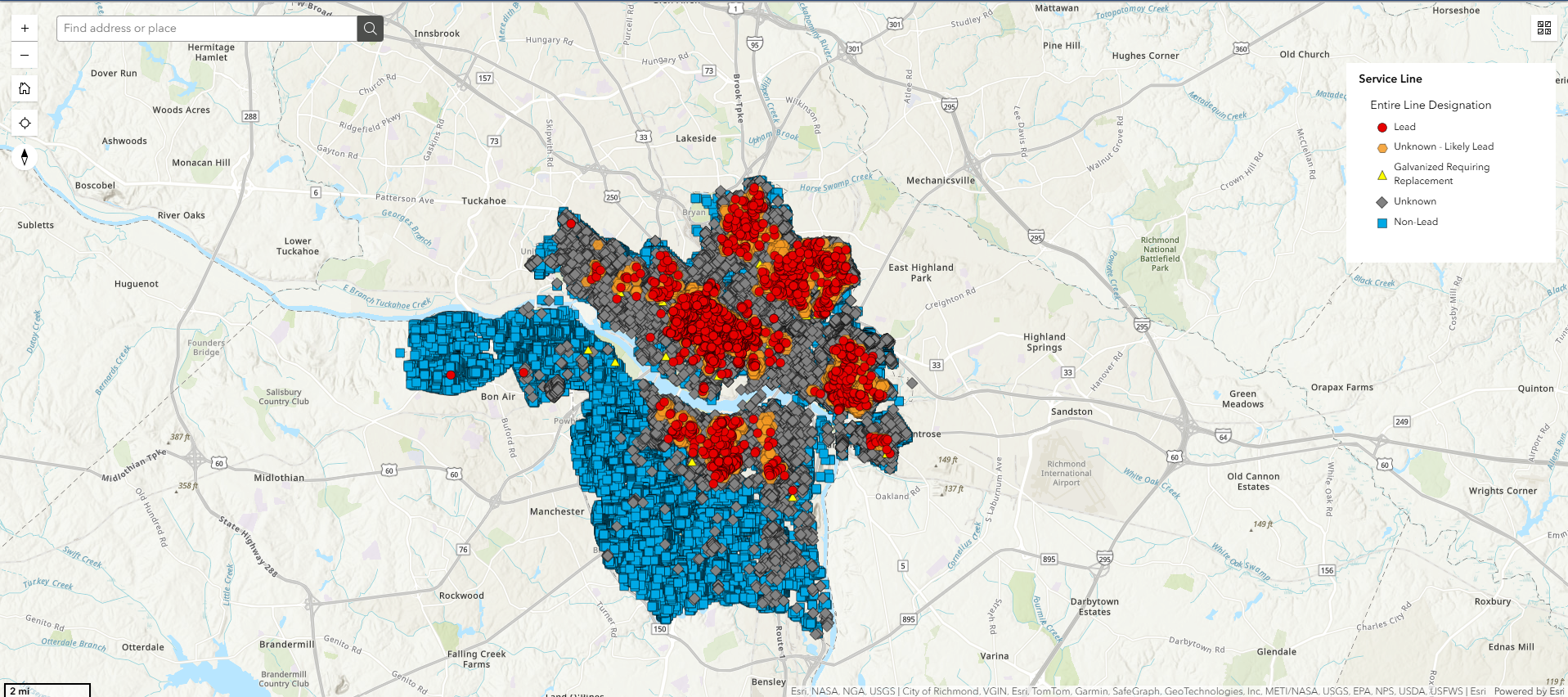

Click here to view the map that identifies the material of water service lines.

Click here to start the survey.

Click here for survey instructions.

Click here if you need plumber assistance.

Wastewater Utility

Richmond's wastewater treatment plant serves approximately 58,000 customers in the city and is the largest of its kind in Virginia. Located along the south bank of the James River, the plant can treat up to 75 million gallons a day of sanitary sewage and stormwater before returning it to the river.

Protecting and improving the water quality and aquatic life in the James River is an ongoing commitment. The wastewater plant laboratory has recently been expanded to perform more technologically advanced water analysis. In addition to the millions that have been spent in wastewater plant upgrades, DPU is also engaged in a $117 million combined sewer overflow control program to protect the river from untreated sewer overflows during heavy rains.

The wastewater utility also operates and maintains 1,500 miles of sanitary sewer, pumping stations, 38 miles of intersecting sewer lines, and the Shockoe Retention Basin, a 50-million gallon stormwater reservoir used during heavy rains.

Richmond is one of more than 950 municipalities in the country with a combined sewer system. and is the largest in Virginia at approximately 12,000 acres or one-third of the City. Before indoor plumbing and wastewater treatment, cities built sewer systems to carry stormwater away from homes, businesses and streets. As the population grew and modern bathrooms came into existence, plumbing was hooked into the these existing storm sewers, making them "combined" sanitary and stormwater sewers.

Combined sewer systems collect rainwater runoff, domestic sewage, and industrial wastewater in the same pipe and sends it all to the wastewater treatment plant. There it all has to be treated and then discharged to a body of water; in our case, the James River.

Combined Sewer Overflow

A Combined Sewer Overflow (CSO) is a discharge of untreated storm and wastewater from a combined sewer into the environment. During dry weather, combined sewer systems carry all the sanitary flow to wastewater treatment plants. During times of rainfall, however, the amount of rainfall adds to the amount of flow going to the treatment plant. This heavier flow is greater than the capacity of the combined sewer system. When the flow exceeds, the capacity, the excess flow is discharged directly to the river at various overflow points in the sewer system. In Richmond, the major overflow points are found on the banks of the James River and Gillies Creek.

Learn more about the DPU’s efforts to manage the City’s combined sewer overflows.

CSO Outfalls

There are 25 CSO outfalls located at various points along the James River within the city's CSO area.

Interactive map of the outfalls.*

Location of CSO areas.

Overflow notification thresholds.

Richmond has posted signs at every outfall, alerting people to the presence of CSOs and warning against swimming during and after rain events. A contact phone number is provided for additional information

Ideally, separate pipes will capture the two types of flow (sewer and stormwater) but the cost would be enormous. Extensive excavation of the city streets to duplicate the piping would be necessary, and this still would not solve the problem of chemicals and other debris that enter our waterways through stormwater pipes and drains.

CSO Outfall Reports

These reports reflect results from new monitoring technology, using sensors and meters in the combined sewer system.

2026 Reports

2025 Reports

2024 Reports

2023 Reports

September 2023

December 2023

2022 Reports

* CSO overflow email notifications are no longer provided, as the interactive map provides that data.

Every day we flush used water down sinks, bathtubs, showers, and toilets. This wastewater travels to the wastewater treatment plant where the organic matter and nutrients are removed during the treatment process. This solid waste is additionally treated to removed disease-causing organisms and reduce odor. The result is biosolids, also known as treated sludge. The term biosolids was created in 1991 by the Water Environment Foundation to differentiate between raw, untreated sewage sludge and properly treated sludge that can be beneficially used as fertilizer.

Wastewater treatment and biosolids recycling is good for the environment. The recycling of biosolids is regulated and supported by the U.S. Environmental Protection Agency. Richmond’s wastewater treatment plant is participating in and has been certified with the National Biosolids Partnership’s Biosolids Management Program (BMP), which continuously improves and advances environmentally sound and accepted biosolids management practices. Richmond is the 32nd organization and the second in Virginia to achieve NBP certification.The City's wastewater treatment plant recycles its biosolids to farms in close proximity to Richmond, which is currently 43 farms in nine surrounding counties, including Amelia, Buckingham, Caroline, Charles City, Charlotte, Cumberland, Hanover, King William, and Powhatan. Biosolids add organic matter to soil, improve soil properties, provide plant nutrients, increase crop yields, and reduce soil erosion.

Biosolids Recycling

The city's wastewater treatment plant chooses to recycle its biosolids on farms in close proximity to Richmond because we believe it is the best option for the environment, public health and our ratepayers. Biosolids recycle valuable nutrients to help preserve family farms in Central Virginia. Biosolids recycling is a cost-effective, sustainable alternative to other management options.

Biosolids Management Program

Richmond has developed a BMP to demonstrate the continuous improvement of its biosolids management practices through careful planning, implementation and operation of our treatment system. Richmond's BMP requires it to demonstrate this performance to stakeholders.

A BMP is a management framework for integrating environmental considerations into the day-to-day operating decisions of its wastewater plant - ultimately improving performance over time. 17 key elements of a Biosolids Management Program form the foundation of Richmond's BMP.

The city is committed to the principles set forth in the National Biosolids Partnership's Biosolids Code of Good Practice. This includes a commitment to beneficially recycle biosolids, to comply with all applicable regulations and to reach out to the public about our program.

About National Biosolids Partnership (NBP)

The NBP was established to advance environmentally sound biosolids management practices through the development of a model BMP, and to assist utility departments to demonstrate a commitment to environmental and operational performance that is above and beyond regulatory requirements. Additional information on the NBP can be found at www.biosolids.org.

BMP Benefits

The city of Richmond's wastewater treatment plant made the decision to implement an BMP for its biosolids program to document its environmental performance and ensure that biosolids are processed appropriately and safely. While a BMP program is voluntary, it requires an organization to look closely at its operational and management practices. It also allows us to surpass minimum regulatory requirements, to stay ahead of potentially more stringent regulations, and to strive for continual improvement.

Contractor performance and expectations

Contractors are selected to recycle biosolids on area farms. Their responsibilities include:

- Determining nutrient loading rate on farms

- Application rate monitoring

- Permitting farms to receive biosolids

- Community relations

Monitoring of biosolids quality

Richmond monitors for nutrients, trace metals, solids content and pH level to ensure biosolids meet standards established by federal and state regulations.

BMP Objectives

Richmond's wastewater treatment plant is committed to continuously improve critical areas of its wastewater operations that demonstrate a commitment to environmental protection and performance excellence. Wastewater treatment plant operators are doing the right things in the best possible way. Key areas of our Biosolids Management Program include:

- Quality management practices

- Public participation

- Regulatory compliance

- Environmental performance

Biosolids Management Policy

Consistent with the City of Richmond’s Environmental Policy Statement, the Richmond Wastewater Treatment Plant (WWTP) is committed to the following principles of conduct set forth in the National Biosolids Code of Good Practice. The WWTP will focus its available resources to produce Class B biosolids. Further, it shall be the position of the WWTP to promote and practice the beneficial use of biosolids and the reuse/recycling of resources. The WWTP will strive to maintain, improve and protect the environment through its treatment/production of biosolids. The WWTP will make every effort to insure that the public is not endangered or inconvenienced by the treatment/production of biosolids at the WWTP or application sites. The WWTP shall obey all applicable federal, state, county and local laws, rules and regulations.

Code of Good Practice

The Code of Good Practice is a broad framework of goals and commitments to guide the production, management, transportation, storage, and use or disposal of biosolids – in short, a comprehensive BMP. Those who embrace the Code and participate in the BMP commit to "do the right thing." Code subscribers and BMP participants pledge to uphold the following principles of conduct:

COMPLIANCE: To commit to compliance with all applicable federal, state, and local requirements regarding production at the wastewater treatment facility, and management, transportation, storage, and use or disposal of biosolids away from the facility.

PRODUCT: To provide biosolids that meets the applicable standards for their intended use or disposal.

BIOSOLIDS MANAGEMENT PROGRAM (BMP): To develop a BMP that includes a method of independent third-party verification to ensure effective ongoing biosolids operations.

QUALITY MONITORING: To enhance the monitoring of biosolids production and management practices.

QUALITY PRACTICES: To require good housekeeping practices for biosolids production, processing, transport, storage, and final use or disposal operations.

CONTINGENCY AND EMERGENCY RESPONSE PLANS: To develop response plans for unantici¬pated events such as inclement weather, spills, and equipment malfunctions.

SUSTAINABLE MANAGEMENT PRACTICES AND OPERATIONS: To enhance the environment by committing to sustainable, environmentally acceptable biosolids management practices and operations through a BMP.

PREVENTIVE MAINTENANCE: To prepare and implement a plan for preventive maintenance for equipment used to manage biosolids and wastewater solids.

CONTINUAL IMPROVEMENT: To seek continual improvement in all aspects of biosolids management.

COMMUNICATION: To provide methods of effective communication with interested parties regarding the key elements of the BMP, including information relative to system performance.

BMP Key Elements

A Biosolids Management Program is a management framework for integrating environmental considerations into the day-to-day operating decisions of a wastewater treatment plant, ultimately improving performance over time.

Read more about the elements here.

Biosolids Reports

The City of Richmond Department of Public Utilities invites interested parties to view the Biosolids Management Program Performance Report, which provides information on the city's Biosolids Management Program (BMP) and the program performance such as regulatory compliance, environment improvements, and our public participation and communication efforts through Nutriblend.

For Pretreatment Program information, click here